University of Michigan’s mBot

Table of Contents

Automate 2025

David Groom writes about Automate 2025 and a visit to Michigan Robotics.

It feels like only yesterday that I headed to Huntington Place née Cobo Hall for North America’s largest additive manufacturing event, RAPID, so I thought maybe I knew what I was getting into in attending Automate, which does for industrial robotics what RAPID does for 3d printing. But it was a completely different scale! This was obvious before I even got there, as the rip-off valet parking across the street was an eye-watering $100 vs. the already outrageous $60 I, as a Detroit event parking ingenue, paid for the previous event. And there was absolutely no parking to be found anywhere near, even for the experienced, like my Amazon buddy who parks there every day, and whose parking playbook fell flat in the face of this mammoth event. All of the locals that I spoke to were blown away by how busy things were, and that was before I’d even walked through the door.

The press room gave access to a fantastic balcony view (below) which gave me a chance to witness the immensity of the event. 17,000+ steps later, I saw enough to fill several newsletters.

Automate 2025 show floor

Perennial friends and supporters of Make:, Digi-Key were there with an impressive booth, creating awareness of how the premium electronic parts supplier can help industrial orgs in the same way that they’ve helped makers and other electronics-focused companies for over 50 years. I was excited to connect with some of the Arduino team that I’d met last year in Rome and at Arduino Day previously, and learn how their Opta PLC line was empowering folks who grew up hacking on Arduinos to build a career in industrial IoT. In addition to some excellent demonstrations, Arduino were also debuting their new Rileva sensor bundle, which includes durable BLE sensors for predictive maintenance and environmental monitoring.

DigiKey booth

One unexpected find was the curiously-named Hellbender (turns out it’s a type of salamander) booth, which appealed to me because it was plastered with Raspberry Pi logos and hardware. After a wonderful conversation with cofounder Adela Wee, I learned that more than just Pis being present in their own AI-driven computer vision systems, they were actually instrumental in the creation of the Raspberry Pi AI HAT+, having introduced the RPi team to Hailo through their own research. Their new RP2350A-based sensor board was an exciting addition to an event mostly filled with giant unapproachable robotic arms, and they also clued me into the fact that Raspberry Pi themselves were somewhere in the previously undiscovered basement area! Raspberry Pi don’t do a ton of events (though it was great to see them at Maker Faire Rome and Bay Area!), but Automate actually turns out to be one of their most important, since around ¾ of their business now comes from industrial solutions, rather than individual makers. There were no new product announcements from the Pi team, but it was great to witness them connecting with an excited industrial audience, many of whom are already building products around the CM5 and RP2350.

I was surprised by the lack of humanoid robots; lots of arms, a few quadrupeds, but no trace of the flashy humanoid future I’d expected to encounter. Plenty of pictures in booths, but I thought more humanoids would be wandering around the show floor in 2025.

One of many fun demonstrations of industrial tech, this robot arm hands out candy!

University of Michigan Robotics

I also got a chance to connect with the University of Michigan robotics team at Automate, and signed up for a tour to see the bipeds, quads, drones, and more that they are working on. Later in the week, Michigan Robotics Managing Director Damen Provost took a group of us on an extensive excursion around the incredible Ford Robotics Building, a purpose-built lab for enabling robotics research.

Managing Director Damen Provost

Starting in the airy yet futuristic atrium/café area, we quickly moved to a three-story fly zone where research was being conducted into drones being monitored and flown without the use of onboard sensors, in the same way as Hollywood mocap balls are used to record performers’ movement. The next room held what might more traditionally be expected from a robotics research lab: bipeds and quadrupeds in various states of experimentation and repair – but was also an amazing history lesson, charting the evolution of early bipeds like Rabbit to the more modern Cassie and eventual mutation into assistive exosuits like Wandercraft.

Evolution of bipedal robots

Our next stop was an exhibit showing off the Open Source Leg which…well, does what it says on the tin, but it was wonderful to hear that the use of open source in this academic project had rapidly accelerated it in ways that a small single team never could. An industrial lab echoed the types of applications that dominated Automate, with robot arms, machine monitoring, and even a Boston Dynamics Spot at work filling buckets of water from a spigot.

The basement held one of the least expensive but most exciting robots in my opinion: the open-source mBot, which puts a Raspberry Pi-powered bot in the hands of every student – a dramatic departure from the more typical experience where years of theory might be required before actual hands-on robotic fun happens in the classroom. I’m actually in talks with the department about teaming up to share mBot with our audience, so stay tuned for that!

A comprehensive makerspace further enables students to get tactile with their learning, offering fabrication often off-limits elsewhere on campus. The Garage held various automotive projects past and present, including a curious inflatable steering wheel that offers haptic feedback to the driver without overloading the senses with yet another flashing light or beeping noise. Outside, a simulated Mars surface enabled…well, testing on simulated Mars surfaces, and an AI-generated rock garden of sorts provided further testing grounds.

Despite numerous “would you like to see one more thing?” extensions, the tour felt over too fast, with all manner of secrets still undiscovered (what was happening to the human subjects in the room whose privacy glass was switched on?!). Honestly, the obvious openness and good will imbued in the department was one of the things that impressed me most about the tour – even the building itself was designed to be open and transparent rather than attempting to hide the research being done within, and frequent surfacing of their values and how they affect their activities and approach left me with the feeling that they were less likely to be producing T-1000s vs. more Open Source Leg-type projects.

Rocky Mountain RepRap Festival

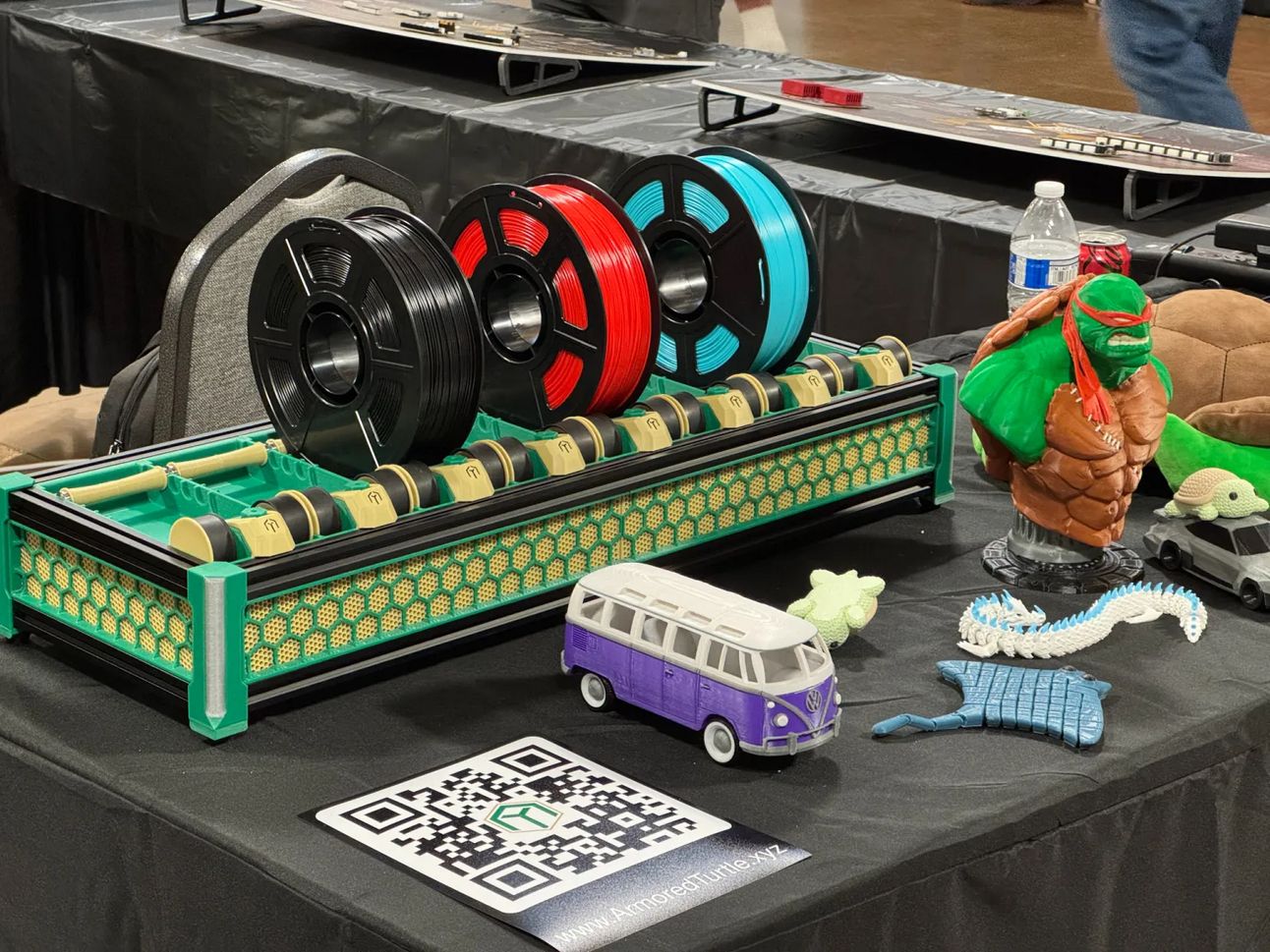

Joan Horvath and Rich Cameron filed a report on the 2025 Rocky Mountain RepRap Festival in Loveland, Colorado.

Multi-color printing was all the rage this year. While there were a few fresh independent dual-extrusion (IDEX) machines on display, these mostly fell into two categories: tool changers and multiplexers. The Prusa XL toolchanger was on display, but there were also several Voron-derived designs. Although Prusa’s MMU has been available for years, filament multiplexing really took off this year thanks to the AMS for Bambu printers and the open source BoxTurtle by ArmoredTurtle for Vorons and other Klipper-based printers.

You can find their full report on Makezine.com.

Deformable Displays

Sam Freeman attended Display Week in San Francisco, May 11-16. You can read his report “The High and Low Tech Behind the Displays of Tomorrow” on Makezine.com. One thing he found was “deformable displays.”

The hissing noise from the pneumatics drew me in, and their display was mesmerizing to watch, not for what it was showing but for how it moved. Shin-Etsu presented a deformable compound-curve 3D display that breathed in and out. It didn’t win any points for resolution, but it’s the only screen I’ve ever seen that bends in two directions without breaking. I can easily imagine ways to use it in wearable projects.

Fireside Chat with Matt Eaton, Robotic Arms author

On Thursday this week, I had a chat with Matt Eaton, whose book “Robotic Arms” was just published by Make:. We were also joined by one of Matt’s promising students, Justin Somerville, who talked about a robotic project he’s working on.

You can buy the Robotic Arms book at Maker Shed. There’s also a new Robotic Arms kit that you can pre-order here.

Make something over the long Memorial Day Weekend in the US and let me know what you did! Email me - [email protected].

Make Things is a weekly newsletter for the Maker community from Make:. This newsletter lives on the web at makethings.make.co