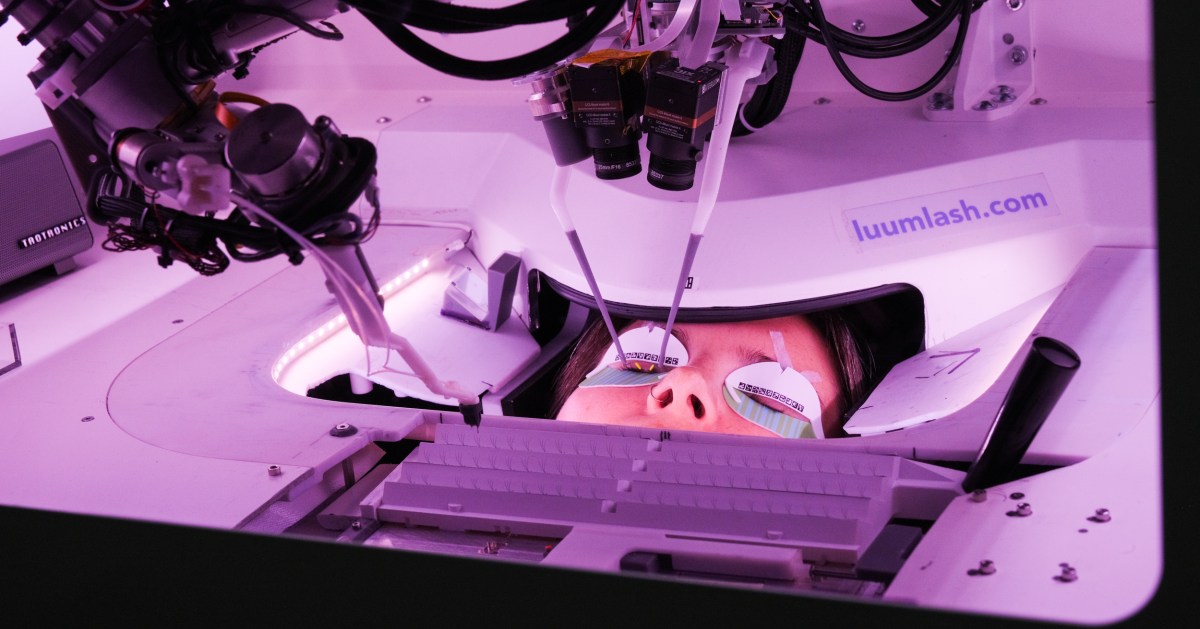

Mona’s feet

Last month, Make: Editor Keith Hammond and I went down to Silicon Valley and met with the founders of two humanoid robotic startups, Kind Humanoid and K-Scale Robotics. Both startups were working out of garages, one in Palo Alto and the other in Menlo Park. A robotic workshop looks a lot like a garage makerspace.

The garage workshop of K-Scale Robotics

I came away these meetings with the idea that we are entering a new wave of robotics, you might say, robots with AI for brains. As one founder explained, AI robots that are able to think can also decide to perform an action. As the Kind Humanoid website says, its robot is “combining the power to reason with the ability to act.” It moves AI into a physical body that occupies the same space that we do.

The physical components of a robot and the processes for making them are familiar and within reach of any maker — these garages have a rack of multiple 3D printers that print out body parts for the skeleton, an electronics workbench and stacks of specialized servo motors from China sitting in boxes waiting to be connected and tested.

Mona

Christoph Kohstall brought Mona to Maker Faire Bay Area last year. Mona was a spectacular sight, a six-foot tall robot without skin encased in glass. Mona was all wires and motors wrapped around orange 3D-printed body parts. I almost didn’t care if it worked; it was a work of art!

Mona at Maker Faire Bay Area 2023 (photo by Keith Hammond)

Kohstall wrote about Mona on LinkedIn: “I locked myself in the garage for 3 years - to create what I see as the most impactful machine that can possibly be created. I built it from scratch with my hands and my own design ethos.”

Christoph with Mona at Maker Faire Bay Area (photo by Keith Hammond)

Christoph has an interesting background with a Ph.D in physics. He was the founder and inventor of a “wearable quadcopter camera” that won the Grand Prize ($500k) in Intel's Make It Wearable challenge in 2015. Then he went to work at Google Brain. A year ago he published the following video demonstration of Mona, saying that he “had given ChatGPT a humanoid body.”

Kohstall and his team are working on a new version called Olympia. (I don’t know how Mona feels about it.) Olympia is sleek, with the technical insides enclosed by a 3D printed hard body. (In the background of the photo is former Make intern, Luke Artzt, is working on CAD files.)

A sleek new version in development is called Olympia

Stompy

Stompy is the name of the robot produced by K-Scale Robotics. Their goal is to develop and prototype an open-source robot that others in the community can build. Their business goal is to become a software platform for these robots. As founder Ben Bolte said on his blog, “We will design the world’s best humanoid robot and give the design away for free.”

Here’s a basic description of Stompy from the K-Scale Robotics website.

Our robot, Stompy, is a 4-foot humanoid robot featuring the claw gripper from the recent Universal Manipulation Interface paper, designed so that each part fits on a 256 × 256 3D printer bed, with a total bill of materials costing less than $10,000. We’re using carbon fiber PAHT, but in principle, any reasonably strong plastic could be used instead. Our actuators are quasi-direct drives with between 6:1 and 8:1 reduction ratios, meaning that all the joints on our robot are low-inertia and back-drivable, with nominal torque values from 3-12 Nm. Each robot features a hot-swappable 48V 15Ah battery pack, which can power it for over an hour.

Versions of Stompy were sitting in the garage workshop as well as in the hallway of the house where Ben and team are living.

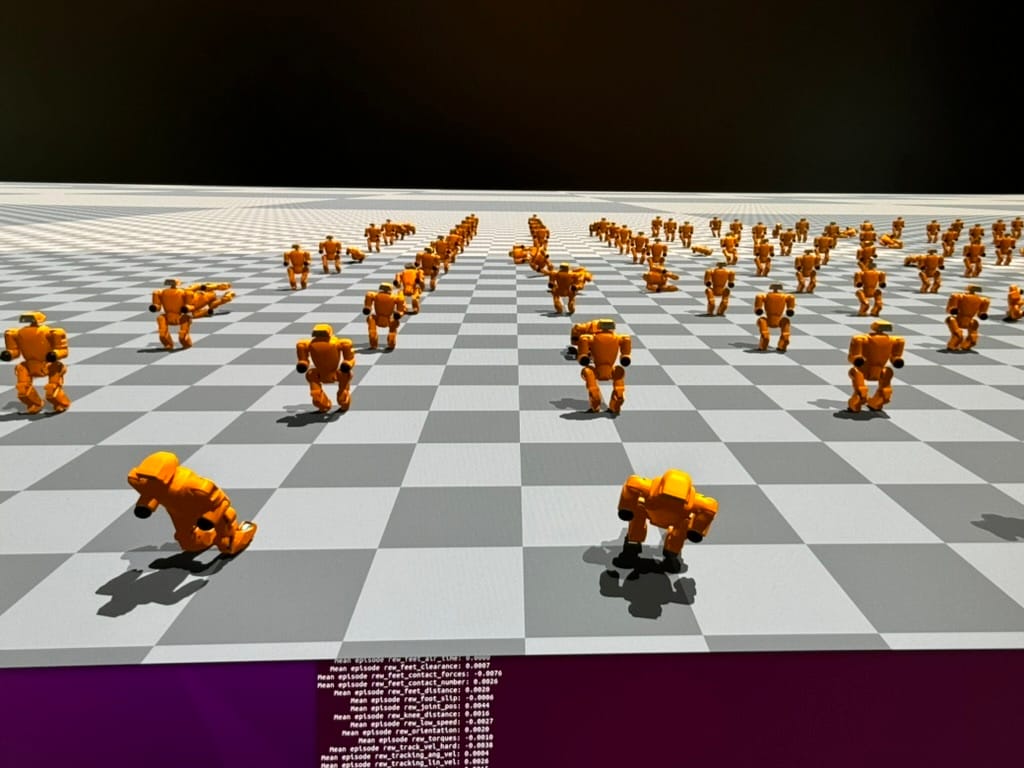

AI is not just the brain of the robot; it’s also figuring out how the robot will learn to do things. Ben said that they aren’t writing programs that tell the robot how to walk. Instead, they run simulations asking the AI to figure out the best way for the robot to stand up and walk. Pawel Budzianowski whose speciality is machine learning is working on it. He showed us the simulations on his screen - some of them keep falling down, like a child trying to learn to walk.

Ben had worked on robots at Tesla and then Meta. He described projects he worked on at large companies and said the project was great but then the project became less a priority for the company — like the VR headset at Meta and the humanoid robot at Tesla. He wrote about K-Scale as an AI startup and he said: “I feel like I am finally doing what I was put on earth to be doing.”

Ben Bolte with a version of Stompy

What exactly can these new robots do for us? That’s still the big question to explore — as big as the mind-body problem. It presents the kind of challenge that makers like to take on and it’s a new frontier. That’s where you find garage startups innovating and exploring the future of robotics. If you’re working on an interesting new robotic project, please let us know for a future issue of Make:.

Providence Maker Faire

This Saturday, September 7, is the Providence Maker Faire in Rhode Island. It will be held at the 195 District Park. If you go, say hi to former Make: editor Brian Jepson for me. Info here.

We’re Hiring

Make: is looking for an enthusiastic maker to work as an online editor, managing content on our website, newsletters and social media. If you like to make things and you like to write, or know someone who fits that description, email me and I’ll send you the job description. [email protected].