Editor David Groom takes a deeper look at the Arduino UNO Q board; David covered the Q launch in Turin last week, along with the news that Arduino agreed to be acquired by Qualcomm. Make: Books Editor Kevin Toyama gives us a report on his trip to Maker Faire Tokyo, which has one of the most interesting group of makers. I talk about the upcoming article on Ponytrap and Quentin in the next issue.

Table of Contents

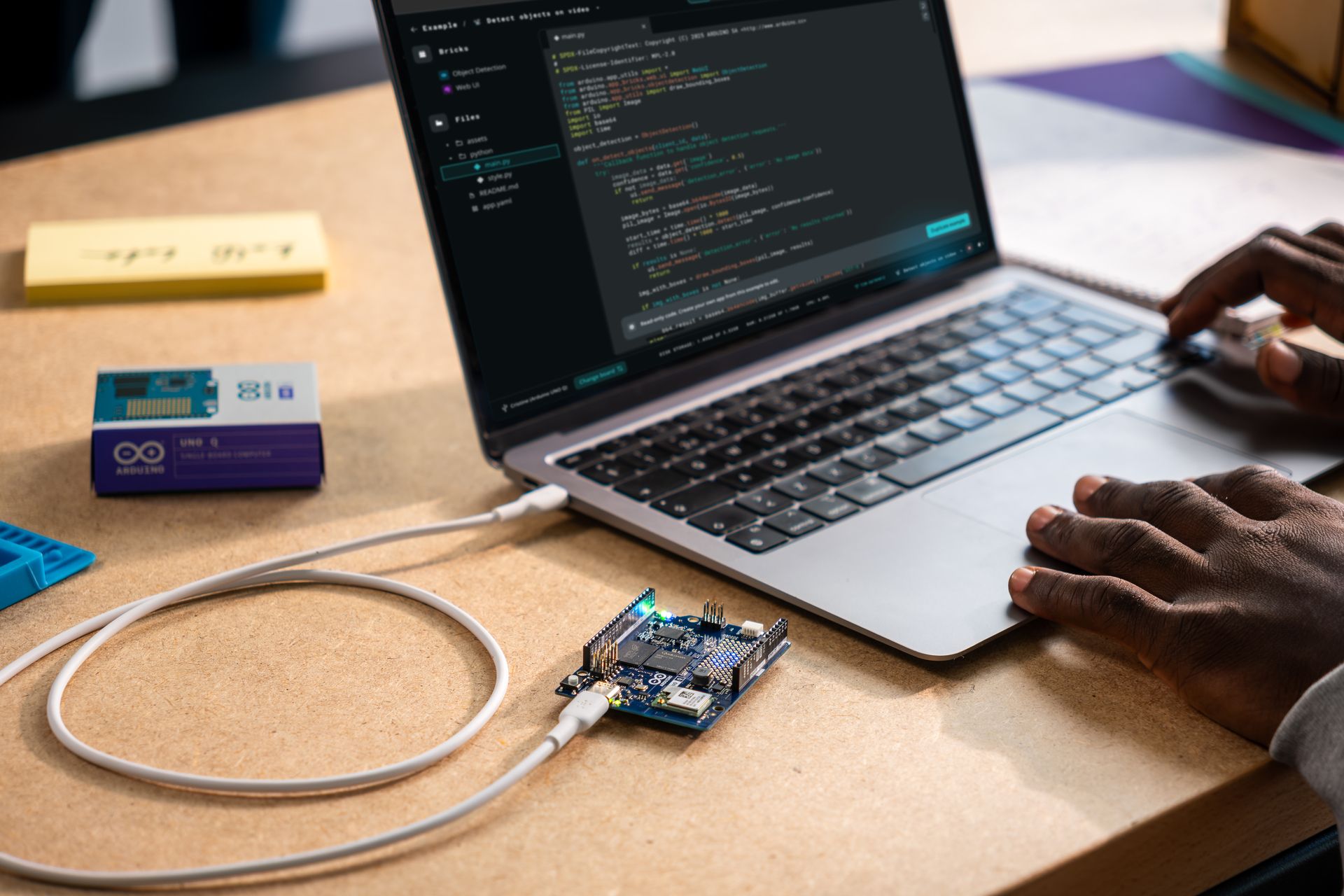

Arduino UNO Q

I was lucky enough to receive an early DVT (Design Validation Test) version of the Arduino UNO Q board in September, though I only had about a day to play with it before shipping it off for our annual Boards Guide’s photo shoot, and after that was Maker Faire Bay Area, a frantic week of shipping Make: V95 to the printers, and then the Q launch in Turin. Now I took a moment to spend some quality time with the board, and will share my findings in this newsletter.

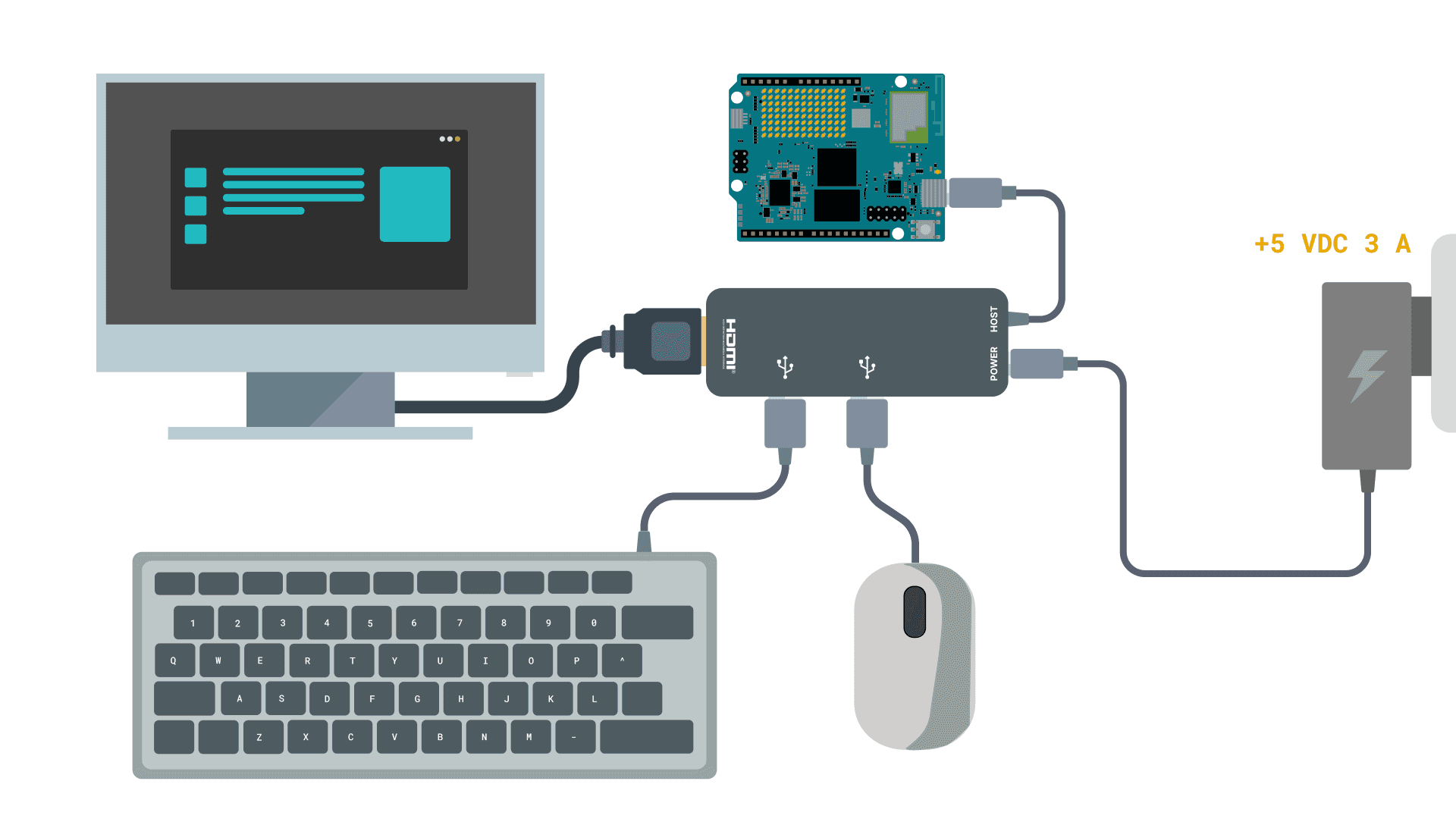

Connecting Arduino UNO Q through a USB hub

One of the revolutionary aspects of the UNO Q is that unlike prior Arduino UNO boards, it does not require a host computer to author code. By adding a USB-C hub, the Q can be used with a conventional keyboard, mouse, and monitor as its own Debian-based PC. This is what I used for initial setup, but after the novelty wore off, I started exploring other modes. Like a traditional UNO, the board can be directly connected to a host machine over USB, although unlike prior UNO devices, it requires a constant connection to the new App Lab software, rather than only really needing plugging in when it’s time to flash or debug code. A third, “network” mode can be utilized after the machine has been connected to your local Wi-Fi network via one of the other two. I actually found this to be the most useful in practice, since my desk is still covered in cables and boards from the dozens of reviews required by this year’s boards guide, and all that’s required for this mode is that the board be powered on and somewhere within Wi-Fi range.

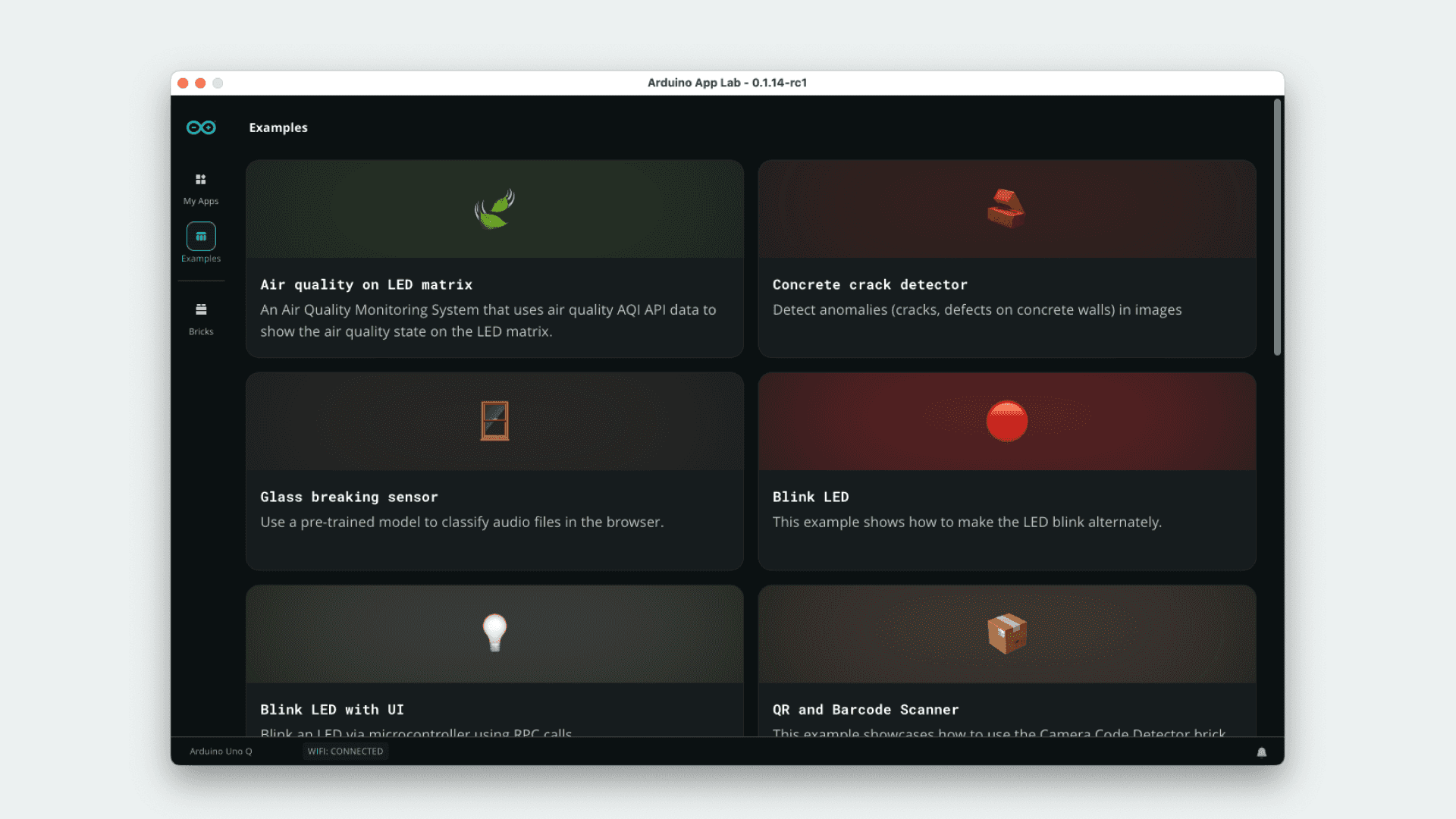

The App Lab software comes with about a dozen and a half examples, ranging from blinking an LED, to blinking an LED using a web-based interface or the Arduino Cloud, to real-time face detection. Many of the examples require accessories, such as USB cameras and microphones, or Modulino modules, so be sure to stock up if you’re planning on working through the entire set.

Bricks and Bridges

One of the most fascinating departures for this board is that in addition to traditional C++ sketches, it has the entire facilities of a Linux-based OS in its arsenal. In the current App Lab software, this manifests in the form of Python and C++ code running in unison within a single “App.” When creating a new app, a main.py is generated, which runs on the Linux CPU, while the traditional sketch.ino runs on the board’s STM32U585 microcontroller. Crucially, the two are able to collaborate via the new Bridge tool, which allows functions to be run and data to be exchanged via Remote Procedure Calls (RPCs). This enables some exciting scenarios, for example using machine learning and a USB camera to detect someone’s mood, and then summarizing it as an emoji on the 8x13 LED matrix.

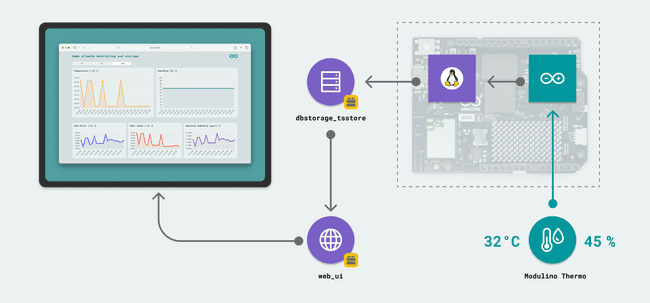

Here’s an example from an App Lab tutorial of a Home Climate Monitoring App, which records data from a Modulino® and streams it to a web server hosting a web application.

Home Climate Monitoring example App

The other important new concept in App Lab is the Brick. I was impressed when trying out the examples that some of them had entire web servers as interfaces, coupled with pre-trained AI models, and SQL databases for data logging. With drastically increased complexity, compared to a simple microcontroller, the combination of Python, C++ (and JavaScript/HTML/CSS if you create a web UI) can start to become overwhelming, especially when you’re just starting out. Bricks abstract away the complexity of an AI model or web server, providing a simple API – not unlike traditional Arduino libraries which drastically simplify the use of complicated hardware. Written in Python, and often incorporating entire Docker containers (which are then interfaced with via Python), Bricks are advanced building blocks on which to construct your app.

Easy as 0.1.23

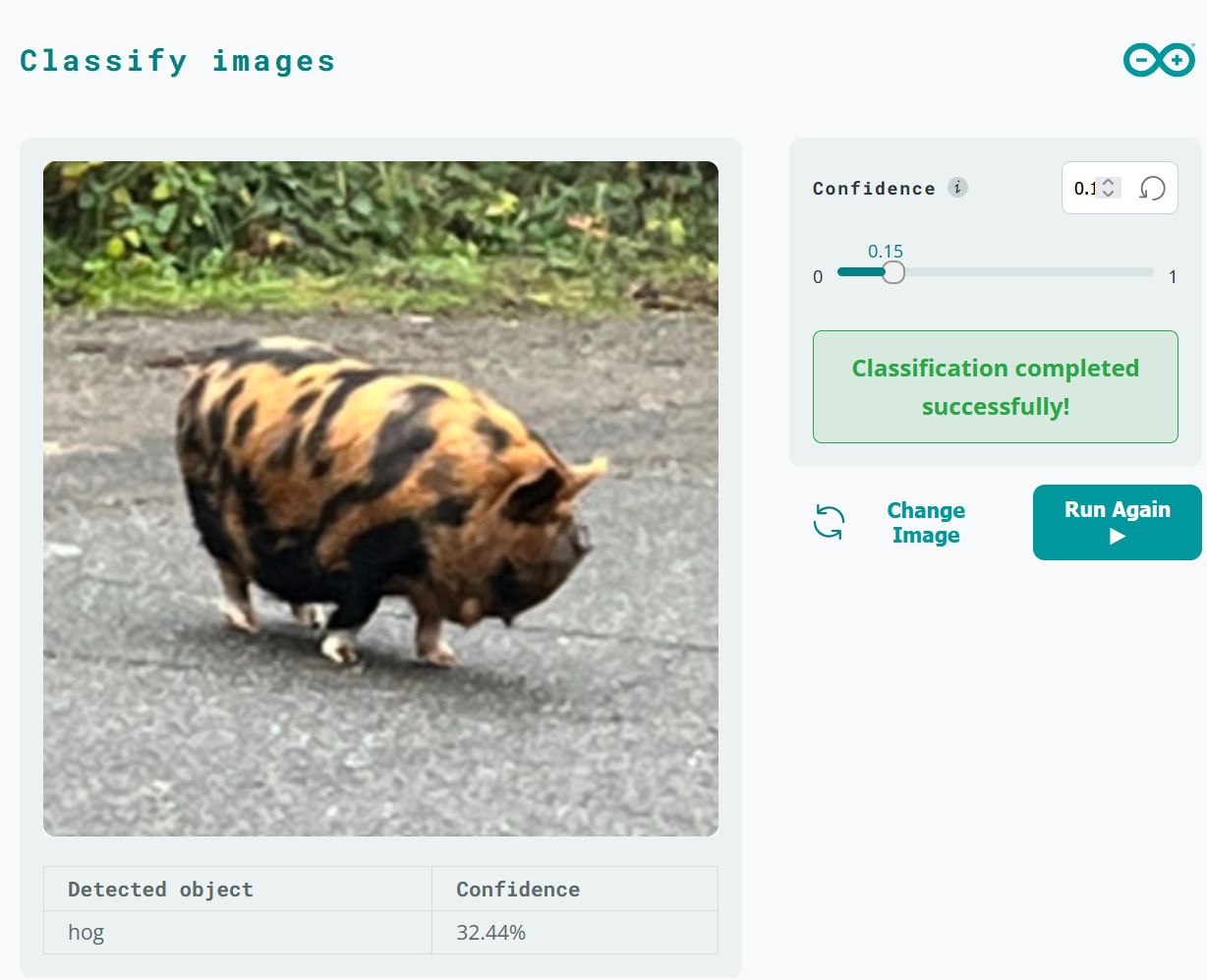

The version of App Lab that I am using is 0.1.23, and this low version number reflects the fact that these are still early days for the tool. UNO Q pre-orders are shipping as early as October 25th, but the software is being continually updated, with new releases seemingly every time I plug it in. This can be rough at times – the most recent update forced me to reset my password for some reason – but given its pre-release status, this is completely understandable. The experience running the examples can also be trying at times – pulling down Docker containers and running them on a Cortex-A53 with 2GB of RAM can take up to a minute in my experience, which isn’t crazy, but can seem like a lifetime if you’re accustomed to instant MicroPython iteration on a microcontroller. Hopefully the upcoming 4GB version, as well as improvements to the software, will speed things up. I also had difficulty getting some of the examples to function, e.g. for image classification I had to turn the confidence down significantly in order to detect anything. Again, I’m considering this “preview” software and will reserve judgement until the 1.0 release.

faQ

So, I assume the Q on everyone’s mind is would I recommend this new UNO? Absolutely! When the team first shared details of the project with me in July, they described it as unlike anything Arduino’s done before (kindly forgetting the Linux-based Arduino Yún and Intel Galileo boards from 2013), and I wholeheartedly agree – this is a giant leap forward in capability compared to anything Arduino has done in the past. With one foot in the UNO world that made them a success (Shield-based microcontrollers with extensive library support) and the other leaning forward into the realm of the single-board computer, along with all the power that conveys (as well as the high-speed connectors on the other side of the board for powerful future carriers), and Bricks, Bridges, and other building blocks to facilitate the harnessing of its power even by beginners, the Arduino UNO Q is an exciting glimpse into the third decade of Arduino.

— David Groom, who is traveling to Maker Faire Guangzhou

Make Editor

Maker Faire Tokyo

A few days ago, I wrote about my amazing experience at Maker Faire Tokyo, where my new friends at Impress Corporation hosted me for their show. (Note: Maker Faire Tokyo transitioned from O’Reilly Japan to Impress Corporation last year and Hideo Tamura and Shoko Chiwata, two of lead organizers, moved to Impress. —DD)

There were more than 250 exhibits at the show, and Impress’s Hideo Tamura said there were twice as many exhibitor applications. That’s quite extraordinary considering what I saw there — the projects on display were extremely polished and covered a wide range of interests. Shoko Chiwata, another one of the show organizers, said they hope to expand next year so even more makers can share their work.

Impress’s Kohei Miki, Hideo Tamura, Shoko Chiwata, with me and my wife

There were so many fascinating projects on display that I saved a few to share with subscribers of Make: Things:

Good Boy

Gaogao wanted a wolf, but wolves are illegal as pets since they’re not domesticated. So, of course, he . . . made one?

Meet Lycan, the robotic wolf. The robotics are impressive, and Lycan can walk forward and backwards, sit, lay down, and wag its tail. But what really caught my eye was how people engaged with it like a living animal.

I think Lycan’s animated eyes play a large role—windows into the soul, and all that. Sensors enable it (him?) to react to different stimuli, like how its eyes change to express happiness when it’s petted. There’s an underlying tension between living things and robots, but Lycan reminded me of Muffit II from Battlestar Galactica, and how people can find real connections with machines.

Towers of Plenty

The Plant Factory Project seems like an endeavor that was regionally influenced, but may have global implications. Since Japan is a small country with limited land available for agriculture, a simple pleasure like regular strawberries is more than twice as expensive as in the United States. (And fancy varietals can be as expensive as $19 . . . per berry!)

But this cultivation system reimagines widespread fields into vertical farms: A Raspberry Pi regulates water amounts, water temperature, and the level of liquid fertilizer to cultivate a garden of plants in the horizontal footprint of a single plant that can grow in an apartment living room.

Strawberries, lettuces, and other plants form an urban garden

Carrot or Stick?

University of Tsukuba graduate student Lankha Isshiki explained her team’s entry in the “Six-Week Project,” where engineering students from her school’s Artificial Intelligence Lab form teams with design students from the school’s Uchiyama Lab, and work within the allotted time and a $50 budget.

Their “Angel and Devil To-Do List” works like this: Users enter tasks and set deadlines into an app, and have a wearable-electronic angel/devil system on their shoulders. If you complete your task on time, you’re rewarded with a congratulations and a cute fluttering of the angel’s wings; if you fail to finish your task on time, you’re punished with a few jabs from the devil’s pitchfork.

After I finished cracking up from the demo, I marveled at the concept of not just having a reward/punishment system for tasks, but how it explores human nature: Would you be more motivated by the potential positive reinforcement, or by the fear of punishment?

Spin Cycle

Kuquri developed this interesting robot that uses three spinning cores for movement. In addition to using spin direction to control mobility, their robot implements a series of interconnected gears within its shell to control the angle of spinning cores and augment its directional range. The result is an unexpected, futuristic fluidity that would look great as part of a future Star Wars droid.

Cool Tool

It’s become depressingly common for a kid to know the ins and outs of a digital app, but not understand how to use basic tools. Yuya Yatsu, the person behind the Shibucho Technical Research Institute blog, is trying to reverse that trend by introducing physical making at a young age through toys.

This toy lathe is actually from a kit in development, with the majority of parts able to be 3D printed. A simple battery-powered motor and gears turn the lathe, and a stationary piece of metal carves into the resin that elicits a mesmerizing sense of satisfaction. The solid resin cylinder’s shavings can even be collected and melted to be used again. What a fun way to introduce kids at a young age to a foundational manufacturing concept!

But here’s a twist: Yatsu actually had generative AI help design the kit, using it to conceptualize the basic form. He then created a CAD model out of that basic design and iterated it to the current form, again using AI to do the tedious gear designs. So while he hopes that young people will rediscover physical maker skills, he is also proof that there’s a place for digital maker skills, and often using both in harmony can lead to fantastic results.

This was my first Maker Faire outside of the United States, and it was fascinating to see how regional culture influences making.

—Kevin Toyama

Make: Books Editor

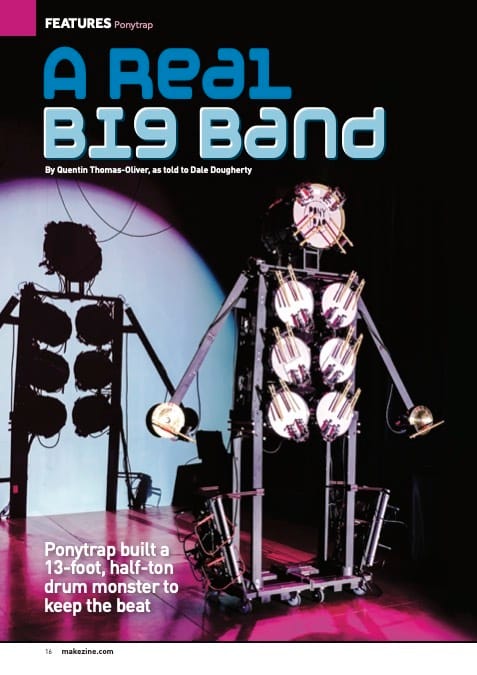

Quentin from Ponytrap

At Maker Faire Lille this summer, I had the chance to sit down with the man behind Ponytrap, Quentin Thomas-Oliver, after one of his performances where he plays a viola with a 13-foot-tall drum machine called Max. An American, Quentin now lives in the Netherlands and he tours with Ponytrap as both a maker as well as a musician.

Dale talking with Quentin at Maker Faire Lille (photo from Maker Faire Lille)

One of the stories that Quentin told me was that when he was living in Austin, Texas, he went to a meeting of The Robot Group and started talking up his idea of building a drum machine.

They were all really nice and welcoming — super eager to help me figure out the project. I said to one of the guys that what I really want to do is make my own Chuck E. Cheese band. He said, “Hold on!” and ran out to his car, returning with a set of mechanical eyes. Turns out he’d been for years one of the few official maintenance guys in the U.S. for the actual Chuck E. Cheese band! I became friends with them even more through the years because of course they’re all going to Maker Faire.

One of the best things I get to do is to talk to makers and learn about the story behind what they do. I like to bring those stories to Make: and in our next issue, you can read about Quentin Thomas-Oliver and Ponytrap — how he became a musician and how he built Ponytrap.

Opener from the Make: V95 article on Ponytrap

Rome and Guangzhou this weekend

Our team is covering Maker Faires in different parts of the world this weekend. Gillian Mutti, our Marketing Director as well as Programming Director for Maker Faire Bay Area, along with Keith Hammond, Editor-in-Chief of Make: magazine, are at Maker Faire Rome, which opens today with an Education Day serving 10,000 students.

Maker Faire Rome on Friday morning (photo by Gillian Mutti)

Editor David Groom is at Maker Faire Guangzhou.

Opening of Maker Faire Guangzhou (photo by David Groom)

This weekend Maker Faire Brno takes place in the Czech Republic. In the US, there are Maker Faires on Saturday in Baton Rouge and Louisville. On Sunday, there is Coney Island Maker Faire in NY. That’s a pretty amazing lineup for a fall weekend introducing more makers to more people, young and old.

If you haven’t been to a Maker Faire outside your home country, check out our global Maker Faire list for a potential addition to your next trip!

Make Things is a weekly newsletter for the Maker community from Make:. This newsletter lives on the web at makethings.make.co

I’d love to hear from you if you have ideas, projects or news items about the maker community. Email me - [email protected].