SpikerBit from Backyard Brains

I’m writing this from the underground hacker’s playground that is All Hands Active! in Ann Arbor, Michigan. Surrounding me are 3D printers, laser cutters, electronic components, and all manner of other parts and tools. Not too long ago, this space also hosted cutting-edge neuroscience research, in the form of Greg Gage and Tim Marzullo’s Backyard Brains. Perhaps best known for remote controlling cockroaches, BYB is back with a new target: human hearts, muscles, and brains!

— David Groom, Make Editor

Table of Contents

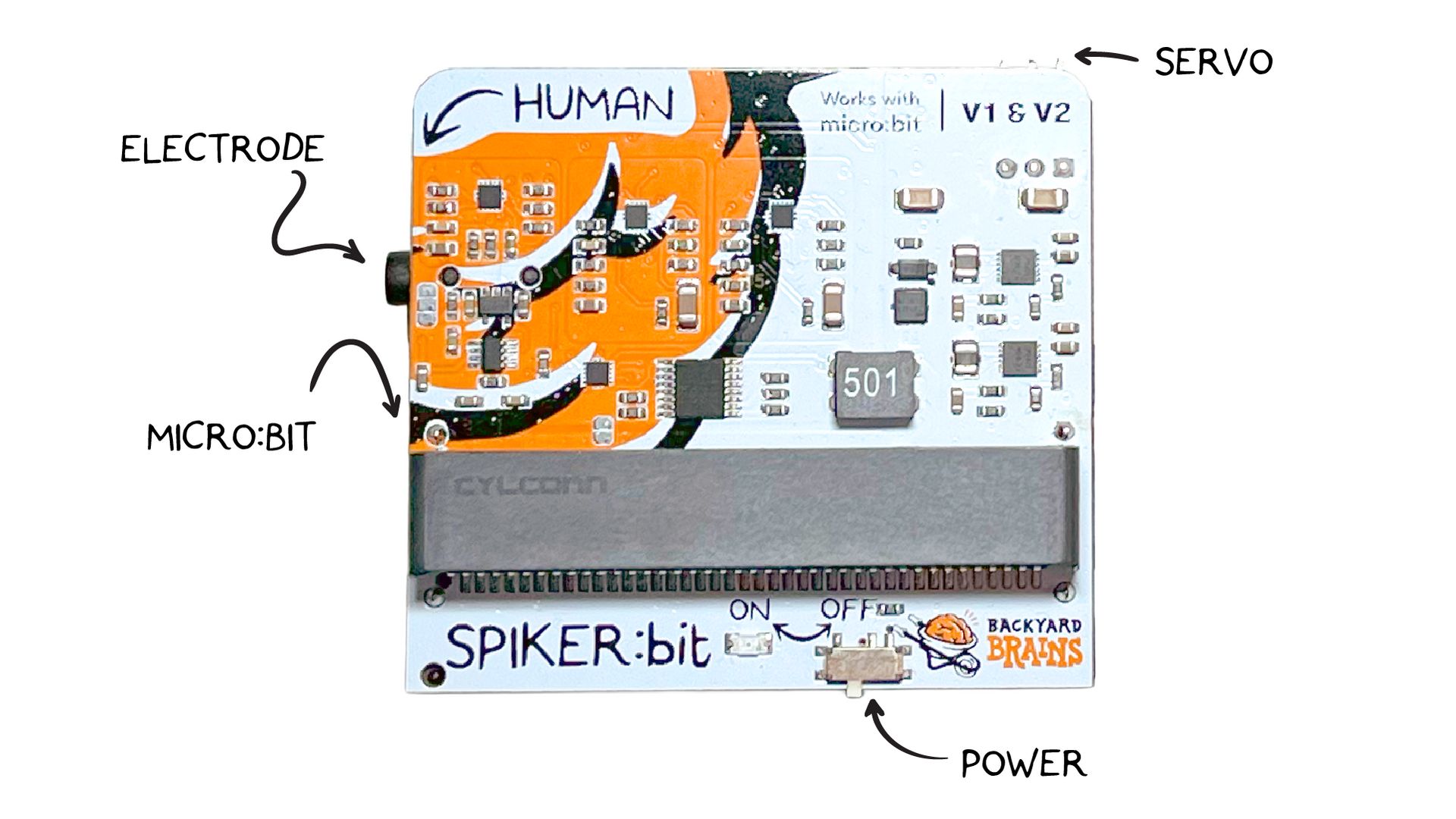

Introducing SPIKER:bit

Backyard Brains’ SpikerBox products have been gleefully reading neurons for many years, but their new SPIKER:bit, as the name implies, harnesses the ease-of-use and incredible ecosystem of the BBC micro:bit to make neuroscience easier and more accessible than ever! I was lucky enough to get my hands on a preview kit, and have been having an absolute blast – in fact, I didn’t even bother taking the electrodes off to write this newsletter, since I’m going to go right back to connecting my heartbeat to various hardware as soon as I finish typing this!

I’m currently working on the annual boards guide, so I’m getting new fun electronics to play with literally every day, but the SPIKER:bit really grabbed my attention due to its unique capabilities. This single board (once a micro:bit has been added of course) allows you to read EMG (muscle) or EKG (heart) or EEG (brain) data using the same electrodes and software tools, and it’s literally as easy as drag-and-drop thanks to micro:bit’s visual coding editor. I just dragged the .hex file from Backyard Brains’ GitHub repo into the web-based tool, and was up and running with a simple heart-rate monitor in about two minutes. But that’s just the start: the fact that you can tap into the entire micro:bit ecosystem means that the EMG/EKG/EEG input can be used for all kinds of interesting interactions and outputs, like controlling a servo, visualizing data with LEDs, or almost anything else you can imagine thanks to the built-in Grove connectors. Although the kit I received is a pre-production preview, there are already tons of wonderfully creative example projects in the early documentation, thanks to the students and makers who have already been hands-on with the prototype.

As always with crowdfunding projects, it’s important to remember that outcomes are not guaranteed and offers expire while you wait, but I’ve know these guys for ages, and they’ve been good friends of Make: since forever, plus I’ve got what feels like polished, production-ready hardware in my hand as I type this, so I would highly recommend that you grab the $70 early-bird while there are still some left (bring your own micro:bit) and start thinking about all the cool projects you want to control with your heart/muscles/brain while you await arrival of your SPIKER:bit in September!

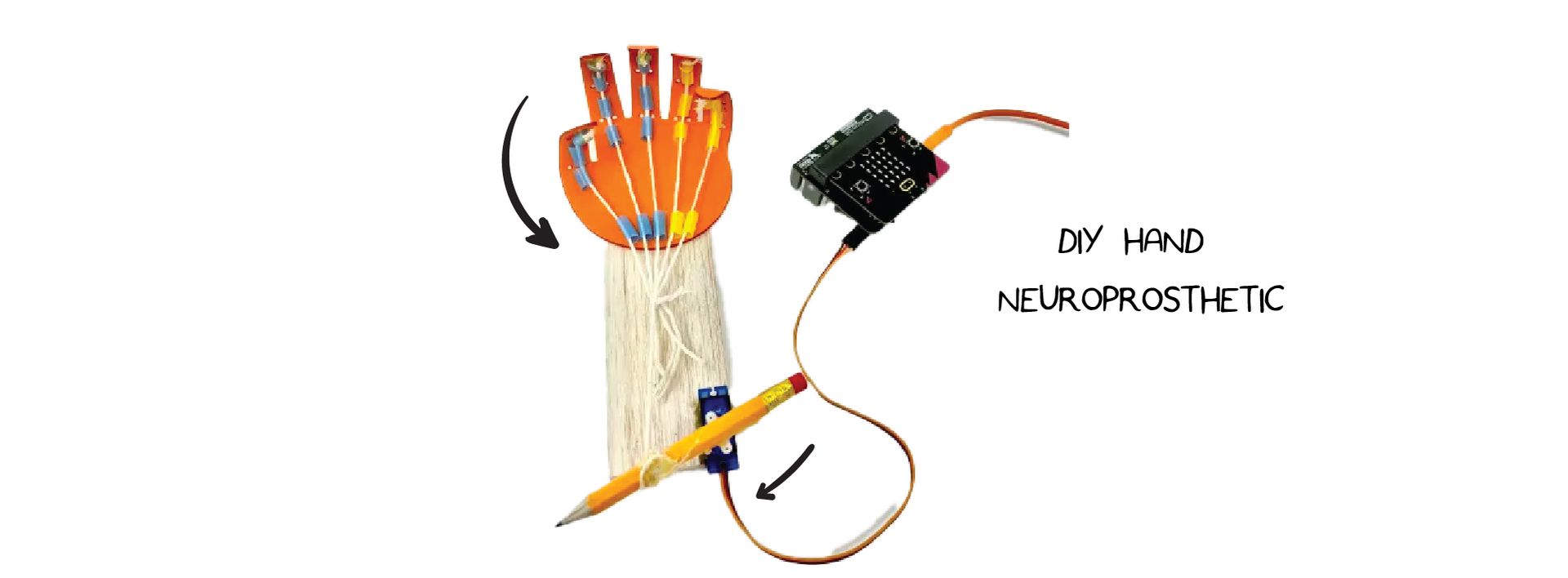

The DIY Hand Neuroprosthetic project is an example of using SPIKER:bit to control a neuroprosthetic hand. Pretty cool.

Make: Vol 94 - Fantastic Realms

I got my issue of Vol 94 yesterday. Yours should be on the way if it not already in your hands. That’s Kayte Sabicer on the cover with her replica of Blade Runner blimp.

Make:Vol 94

Tell a friend about Make: magazine. Word of mouth is the best way for us to get new subscribers.

University Makerspaces — Fireside Chat

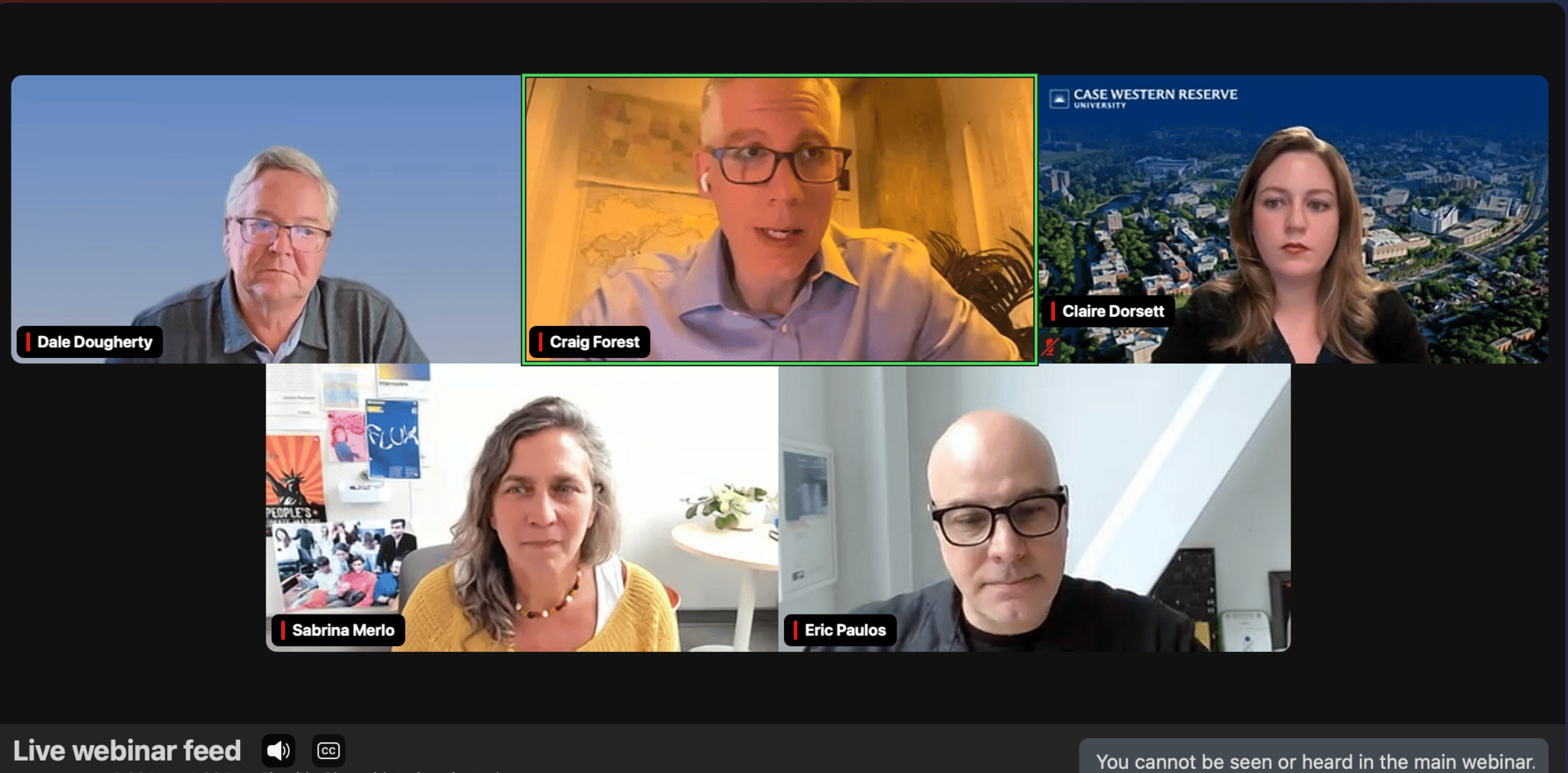

Next week is ISAM — the International Symposium of Academic Makerspaces, which will be held at UC Berkeley August 6-8. About 400 attendees are expected. Earlier this week, I hosted a livestream with some of the organizers of the conference to talk about the conference and more generally the development of makerspaces as an integral component of a university campus.

Eric Paulos, Professor of EECS and member of the Berkeley Center for New Media

Claire Dorsett, Executive Director of Sears think[box] at Case Western Reserve University

Craig Forest, Professor at Georgia Tech’s George W. Woodruff School of Mechanical Engineering

Sabrina Merlo, Senior Director of External Affairs at UC Berkeley’s Jacobs Institute for Design Innovation

What distinguishes makerspaces on campus from machine shops is that students are able to use the tools and the space, even for personal project, not just class projects. As Eric Paulos said, makerspaces are interdisciplinary, and can bring people together outside their field or discipline.

Call For Makers still open for Maker Faire Bay Area

Don’t be shy. I have in the past had to urge makers to bring their projects to Maker Faire, disregarding their comments such as “I don’t know if it will be ready” or “I don’t know if it’s good enough.” I say, bring it anyway and the feedback you get will really help you understand your own project. If you’ve been working on a cool project or your company has a cool product to demo, there’s still time to exhibit at Maker Faire Bay Area.

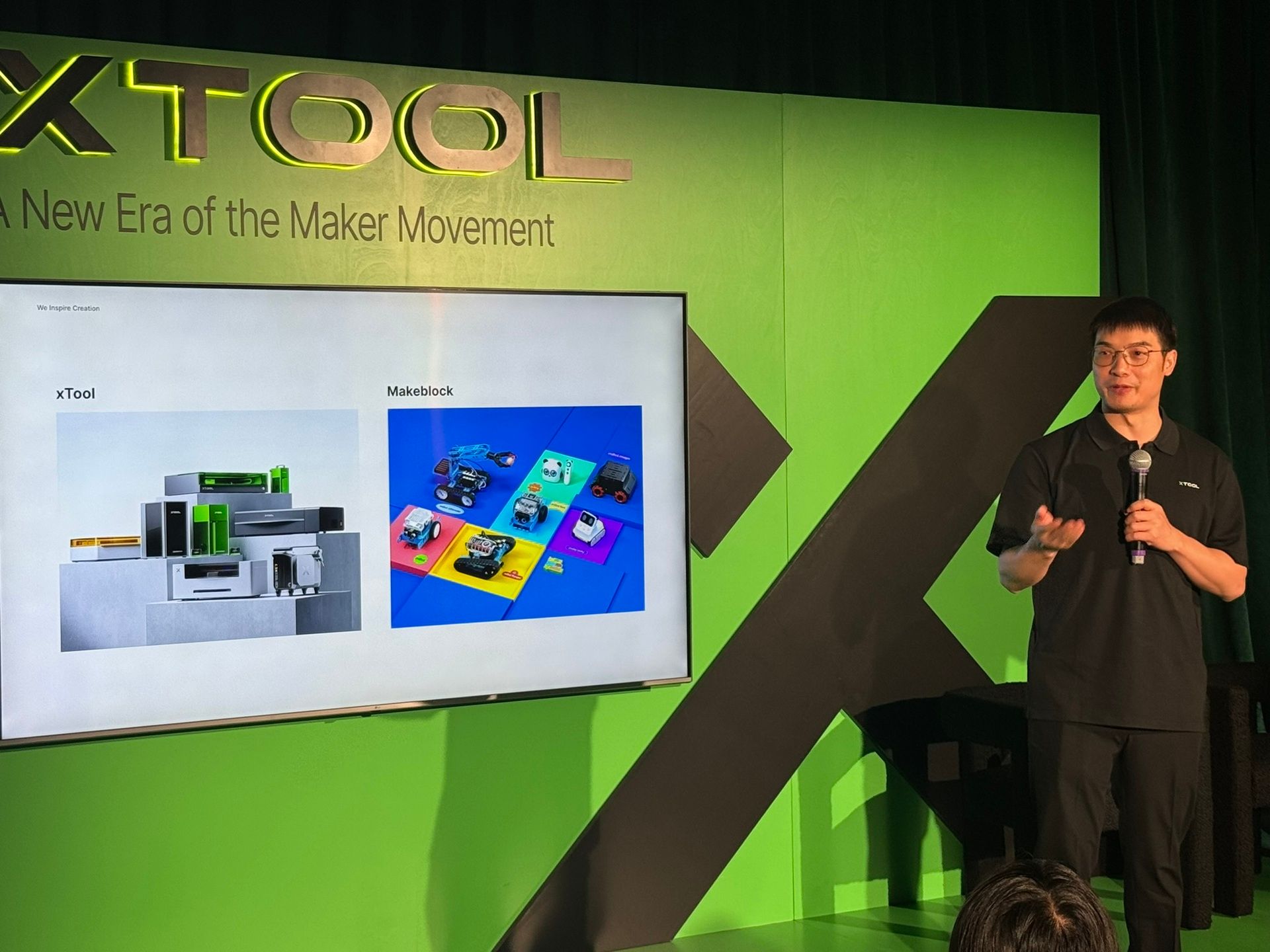

XTool Launch Event

Last night in Mountain View, CA, Jasen Wang of XTool held a launch event not only to announce some new products but also to show off their new US headquarters in Silicon Valley.

Jasen Wang, CEO of XTool (photo by Dale Dougherty)

Long-time readers of Make: may remember Makeblock, a robotic construction kit and series of educational products. I met Jasen at Maker Faire Shenzhen in 2015 and wrote “Makeblock: A Construction Set for the 21st Century.”

As Jasen explained at the launch, Makeblock has morphed into XTool, in part because the Chinese government began to regulate the educational market. Now, they have a complete line of cutting tools, with the flagship product, the XTool P2S 55W Desktop C02 Laser Cutter. They were also demo’ing the XTool MetalFab, a digital welder and CNC cutter. Another intriguing product was the XTool Apparel Printer, which allows you to do screen printing and other ways of printing on fabric. Their business is focused on education, retail and creator/maker market segments

XTool MetalFab (photo by Sam Freeman)

In an interview with Make: Editor in Chief, Keith Hammon, Jasen Wang said: “I think people want to work with metal but the tools are hard to use, expensive, and they look dangerous. MetalFab is solving some of these problems, making it easy for normal people to do metal cutting and welding, and the price is relatively good. We hope to make metalworking as popular as woodworking.”

Metal cutting example (photo by Sam Freeman)

The theme of the event was that XTool wanted to start “a new era of the Maker Movement.” I gave a short talk about how I appreciate what XTool is doing to reach new people and to lower the bar for more people using tools to make things.

Editor Sam Freeman using the digital welder (photo by Keith Hammond)

Make Things is a weekly newsletter for the Maker community from Make:. This newsletter lives on the web at makethings.make.co

I’d love to hear from you if you have ideas, projects or news items about the maker community. Email me - [email protected].