The Mini Cooper Cluckman will be at Maker Faire Lynchburg this weekend (photo by Vector Space)

Welcome to the second issue of Make Things, a weekly newsletter for the Maker community from Dale Dougherty and Make:. This newsletter lives on the web at makethings.make.co

Table of Contents

Lynchburg’s Vector Space

Elise Spontarelli and her husband, Adam, run Vector Space in Lynchburg, Virginia. This weekend, they will be organizing Maker Faire for the community.

DD: Can you tell us about what you have planned for Maker Faire Lynchburg?

LS: This year at Maker Faire Lynchburg we're adding Power Racing! After traveling to Orlando to help produce their Faire for two years, we consulted with their team and connected to the Power Racing Series organizers in Chicago, and decided to add a new event to the circuit in Central Virginia. We built a new kart here at Vector Space (shown above), and have competitors joining us from Chicago, New York, and Louisville. This is an event within the Faire that I would not have had the capacity and knowledge to incorporate without the knowledge sharing from our friends in Orlando. I encourage all Maker Faire producers to get out there and visit other Faires!

T-shirt making during Maker Faire (photo by Vector Space)

DD: How is Vector Space doing?

LS: Vector Space is great. We moved one year ago to a newly purchased 23,000 sq ft space, which doubled our physical footprint. The capital campaign included $150,000 in new tools and equipment, so it has been a busy year setting up shops, installing tools, and continuing to run a 24/7 makerspace. We continue to become a more efficient, better functioning makerspace with each year.

DD: It's been four years since the beginning of Covid. I recall talking to you during Covid. How did you and your makerspace come out of Covid?

LS: COVID started out a scary time for community spaces, with the thought that our ethos of shared space was potentially over. Like many spaces, though, we quickly found a way to help our local community and have come out of the pandemic stronger than ever. We have observed some interesting changes in our small city, with many people moving out of bigger cities and into smaller communities where the cost of living is lower, access to outdoor recreation is better, and remote work is possible. While Vector Space was a novel concept for Lynchburg-ers when we started 8 years ago, migrants from larger cities are more familiar with the concept and often view makerspaces as a positive sign of the culture of a community.

DD: What is your feeling about making and makers in Lynchburg and surrounding areas? Are you seeing new interest?

LS: Right around the pandemic we made a change to our membership enrollment that had and continues to have a positive effect on growth at Vector Space. We now open enrollment 3x per year, onboarding 25-30 new members in a cohort model that allows for Orientation and Safety Training to be concentrated in those months. This allows new members time and space to get acclimated, while ensuring that we have sufficient staff/instructor resources for both new member training and regular classes throughout the year. This has also produced an unexpected "scarcity" that makes membership even more appeal to some individuals.

DD: Enrolling new members 3x a year is an idea I haven’t heard before. It’s good for the space and new members both.

Welding at Vector Space (photo by Vector Space)

DD: Do you have educators involved in Maker Faire and your makerspace?

LS: We have partnerships with several local schools, including public and private K-12 as well as local colleges. I'll share two examples that we are excited about. Students at the University of Lynchburg enrolled in the Advanced Sculpture class in the Art Department spend their Spring semester at Vector Space. The class takes place at the makerspace, where students learn welding, graphic design, CNC plasma cutting, bending, and grinding. They make several individual projects, and the semester culminates in a piece of public art built by the students for the community. After two years of piloting this program, UL has just signed on for three more years of partnership. Likewise, Randolph College has just added an entrepreneur class to their program of studies for the Fall that will also be a collaboration with Vector Space.

We will teach CO.STARTERS, a ten-week entrepreneur training program, alongside hands-on maker skills like 3D printing, laser cutting, graphic design, soldering, and more. The goal is for students to develop a business plan as well as a prototype for their entrepreneurial endeavors.

Assembly Lesson

I bought a next box from HenGear for my chicken coop. The chickens have been eating their own eggs and this nest box has a slope that allows eggs to roll away from the chickens.

It arrived in a flat-pack box and required assembly. It took several hours and I made a number of mistakes in the process but I did complete it. One lesson I learned: walk away when you get frustrated and then come back and look at it again with fresh eyes.

The US-based manufacturer provided a decent manual printed in color and videos of the assembly online and the instructions were pretty clear. However, they used a 3D modeling program for the print illustrations and the video, and I found it hard to see the metal parts clearly and how they aligned with each other. Lots of gray on white.

I realized about midway that I had not really understood front and back, top and bottom, right and left, which were used in the instructions. I had to study the illustrations of the completed nest box to orient myself. The lesson was that I didn’t have the big picture in mind; all I had were the components and steps. The other challenge was having to tighten nuts on screws in hidden corners where I could not see what I was doing and could not fit a wrench to hold the nut.

Next, I have to mount the nest box on the back of the chicken coop and see if the hens will use it. The red material on the nest box forms a privacy curtain for the modest hens.

The assembled Hengear nest box on my kitchen counter.(photo by Dale Dougherty)

$500K funding for makerspace in Brownsville, PA

In Brownsville, PA, a local news article about Team Humanity and Verticals Makerspace and Entrepreneurship Center reported that the organization had received a $500k community development grant “to turn what was once a blighted area into a community asset.” The makerspace focuses on underserved youth to “provide access to top-of-the-line educational equipment, instruction and experiences in a creative and stimulating environment.”

I liked this quote from founder Will James.

“I got here in mid-2013 and started our activities with Team Humanity, and I said our greatest resources are no longer in the coal mines, but are in the minds of our youth. We’re creating spaces so our youth can ride alongside, if not ahead, of the global competition.”

It’s an investment in developing human potential.

Ned Patton’s Material World

Use of new materials is an underdeveloped area for us at Make:. Ned Patton explains composite materials in his book, The String and The Glue of Our World. With more than 40 years experience in R&D, Net writes for the curious citizen scientist or maker, explaining the why and how of composite.

Join me for a Fireside Chat with Ned Patton on April 3rd at 4pm. We’ll learn more about his book and how he learned about this subject through his job.

Register here to join Ned Patton and me for our conversation about composites. Feel free to send questions in advance or use the Q&A during the session.

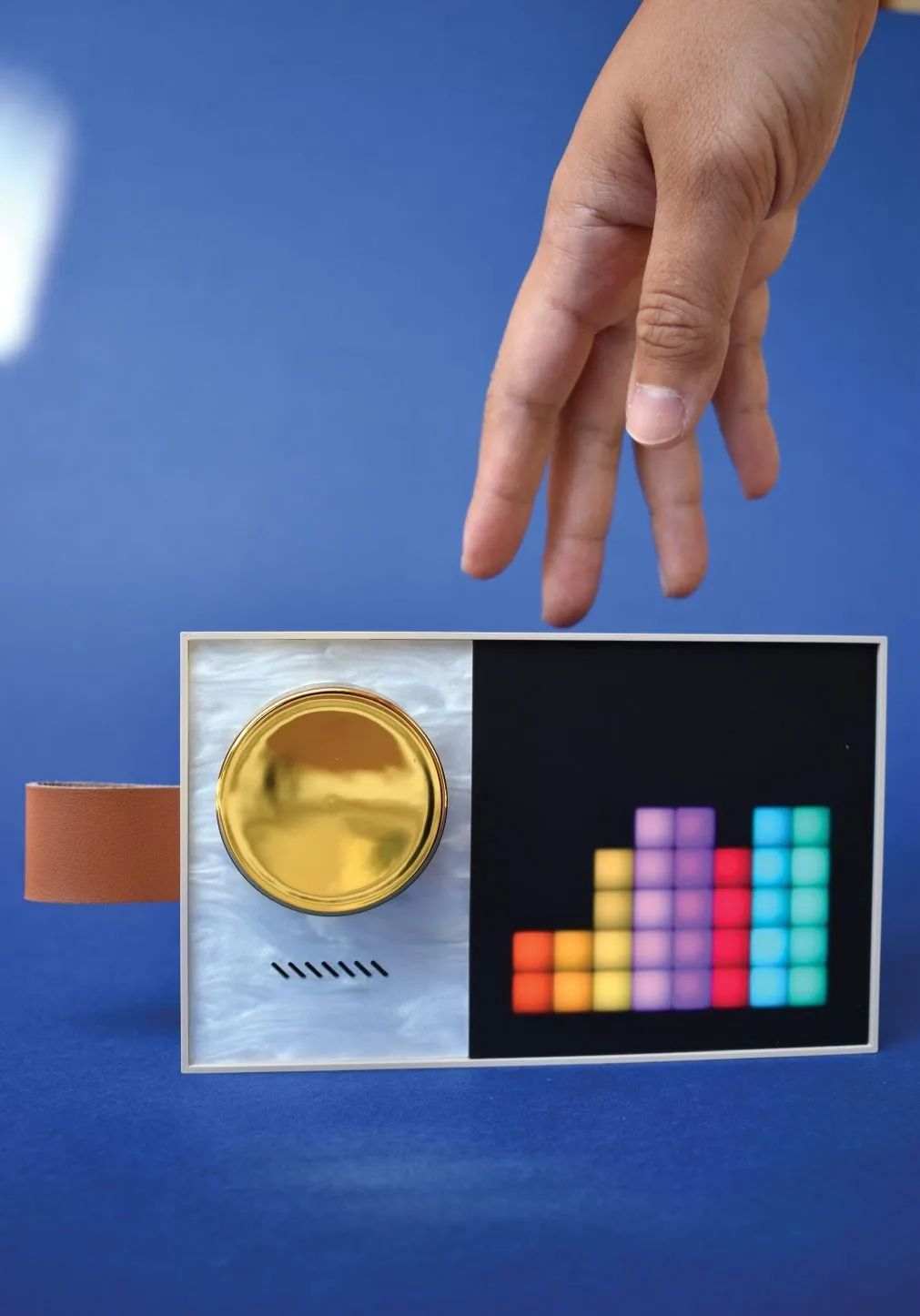

Charlyn Gonda’s Personal Pixel Device

Charlyn Gonda from Alameda, Californias and takes the ferry to work. She wanted to build a customizable clock and she showed us how she did it in Vol 88. On her webiste, charlyn.codes, she describes herself “as a coder by daylight and a maker by moonlight.” Obviously, we like Charlyn’s moonlighting.

Charlyn showed us her Personal Pixel Device at the Vol 88 Launch Party.

I’d love to hear from you if you have ideas, projects or news items about the maker community. Email me - [email protected].