Marleen Stikker of Waag Futurelab referenced Make:’s motto “If you can’t open it…” in her talk “Maker culture is the basis for strategic autonomy.”

FAB25 was held over this past week in the cities of Brno and Prague in Czechia. Organized by the Fab Foundation, the conference moves to a different city each year and brings together many from the Fab Lab Network, which was started by Dr. Neil Gershenfeld at the MIT Center for Bits and Atoms. Prague is also the home of Prusa Research and Josef Průša gave a provocative talk on Thursday about the difficulty of continuing to produce designs under open source hardware licenses for 3D printing.

Table of Contents

Is China using the patent system to gain total control of 3D printing?

At FAB25 Conference in Prague this week, which was held less than a mile from the headquarters of Prusa Research, Josef Průša said in his keynote that China’s aggressive pursuit of 3D printing patents since 2020 was a “minefield” that was killing open source hardware in 3D printing. He wrote in more detail on his blog, saying that “Open hardware in 3D printing is dead - you just don’t know it yet.”

According to Průša, starting in 2020, the Chinese government declared 3D printing to be a strategic industry for China. As a result, four of China’s 3D printing companies ramped up the number of patents on 3D printing, going from filing 40 applications in 2019 to 650 in 2022. The likelihood that these Chinese patents would be accepted in the US and EU is a big concern for Průša, as is having limited resources to fight them. “Even though prior art exists to invalidate the patents, the legal process is expensive.” The openness and sharing of designs that are made possible because of open source hardware licenses can also be exploited to turn open IP into closed IP through the patent system. Once these companies obtain patents, they can sue other companies to prevent them from using these designs without a license.

(Data from Espacenet International Database by European Patent Organization, March 2025) (Průša)

Průša pointed out there are very few 3D printer manufacturers with viable businesses outside of China. PrůšaResearch is an exception. Ten years ago, nearly every country had its own 3D printing company.

China’s support for the 3D printed industry is intentional, giving them an overwhelming competitive advantage and allowing them to dominate the market. He suspects that many 3D printer models from China are sold at cost. These companies can afford to do it because of the way they are funded by the government.

MakerBot caused a stir by changing from on open source hardware license to a closed license for its Replicator 2 model in 2012. Průša was one of those commenting about it on Twitter.

Rob Giseburt wrote about it on Make:

About a year after the closed source announcement, MakerBot was bought by a larger company (Stratasys) and then in 2022, it merged with Ultimaker to create a new company— UltiMaker, which is headquartered in the Netherlands. Ultimaker was known for producing an open source hardware 3D printer.

Watching cheap clones enter the market was the motivation for MakerBot’s decision, which also led to them delaying the announcement of new features in a product roadmap. However, Průša is making a different case against continuing with open source designs, based on his competitors’ ability to obtain patents and then sue him.

Like MakerBot, the origins of Průša’s business started with him making improvements to the RepRap project, starting in 2012. He released his changes back to the project. At FAB25, Průša said that when he was building his first RepRap, “I was a little bit lazy and I liked to do things efficiently,” and he asked himself how he could make it easier. Soon, working with others, Průša found it possible to build a printer over a weekend. People began asking him to supply the parts to build a printer as a kit. He dropped out of university where he was an economics major and started working out of a basement in Prague. He borrowed about €10k from his father, the minimum required to set up a limited liability corporation (LLC). By 2015, he had released a commercial kit 3D printer.

Now Průša Research, which he runs with his brother, has four manufacturing locations in Czechia and a new 90,000 sq ft location in the state of Delaware that has begun producing 3D printers for the US. (Průša didn’t think that the US plant will allow them to avoid the new tariffs because many parts have to be imported, and those are subject to tariffs.)

FAB25 attendees who came to Prague from around the globe toured the Průša factory. I was given a tour by Josef himself. We arrived as the 6am–2pm shift was leaving and the second shift was arriving. (There seems to be a dress code set by Josef — everyone seems to be wearing black, most of them wearing Průša t-shirts.) On one floor, the team members are assembling printers, which sit on carts that are wheeled from one person to the next.

Průša said repairability is a design goal. “You can fix the machine with a hammer and a screwdriver,” he said. I asked Josef if he could see an automatic assembly line replacing his assembly workers. He said, no. He explained that the box uses screws instead of glue or welds. Automation does not work as well with screws and screws allow the user to fix the machine themselves.

He was obviously proud of his factory and how they make things, and it’s really hard to imagine all the work it took to build this operation. In his office, Průša discussed the problem of open source hardware and the apparent strategy of Chinese 3D printing companies to file for lots of patents. He also talked about the tax breaks, loans, and research grants that China makes available to these companies. Later, just after midnight, Průša sent me a draft of his blog post, saying he finally got around to writing down his thoughts. He was ready to speak out. Here’s a link to his talk on YouTube.

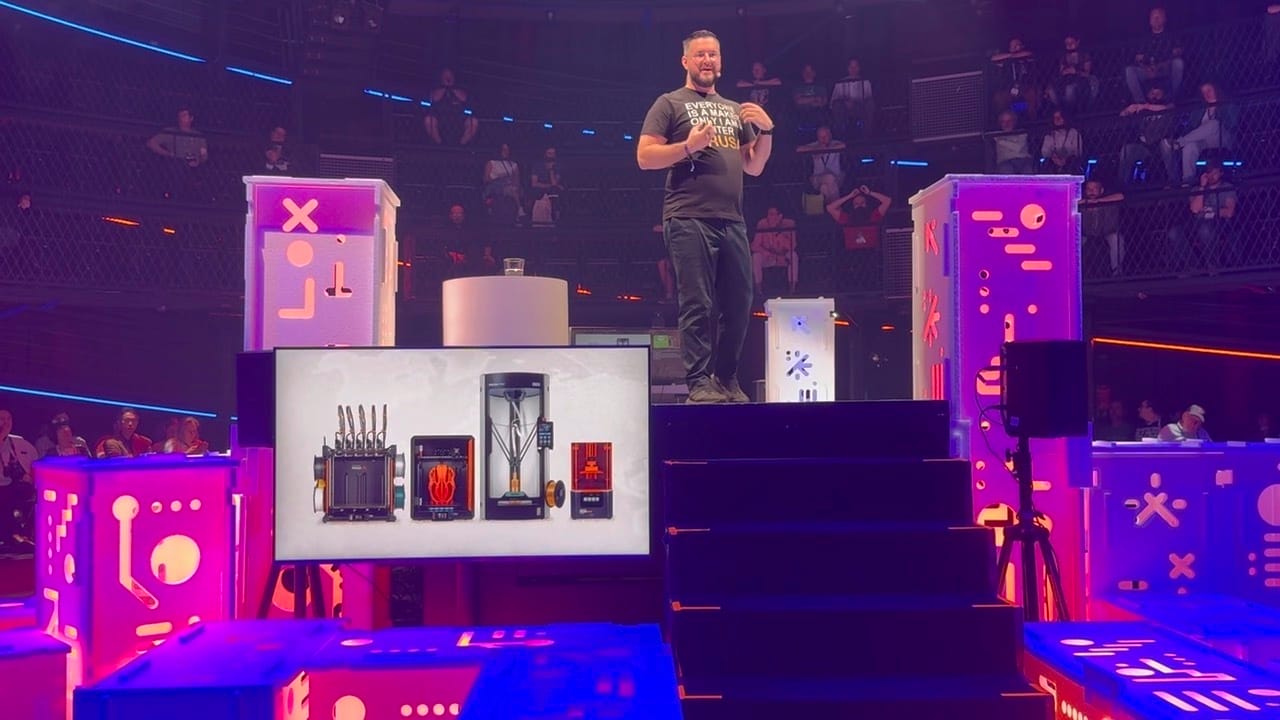

Průša on stage at FAB25

Průša showed off their different models of 3D printers and new software. “It’s great that we make everything under one roof,” he said. “There’s 1100 of us,” speaking proudly of his team.

“To be able to manufacture our machines efficiently, we had to find the lowest common denominator of the technologies we can use to manufacture around the planet. I call it low-tech high-tech because our added value is about the 3D printed part,” he said. “You can still make nice things using low tech out of necessity.” He said that 90% of the parts come from Europe, mostly in Czechia and only 10% of the parts come from China.

He’s invested millions in machinery and in buildings to make printers at scale and in his home country. He’s a remarkable tech success story for Czechia and a maker startup success as well. He’s right to be worried about a competitive threat that he can’t easily control.

“(They) just patent spam every little variation of the stuff out there. And that is why open hardware is very disadvantaged,” he wrote. They can patent designs that are already in use or do minimal modifications to it. “From what we’ve seen, the validity checks (by the patent office) are not stringent at all and prior art doesn’t seem to matter much.”

Massimo Banzi speaks out

It was great to see Massimo Banzi give a keynote at FAB25. He has been on a sabbatical from Arduino and I haven’t talked to him in person since before Covid. In his talk, he covered the lessons learned from 20 years of Arduino.

Massimo Banzi on stage at FAB25

In the Q&A that followed, he was asked whether he would make Arduino open source hardware if he had to do it again. Banzi, who qualified his answer by saying that it was only his personal opinion, replied that knowing the problems that he has faced retaining control of Arduino and protecting it, he would not do an open source hardware license again. One problem was the cloning of Arduino by many Chinese manufacturers. His main problem. however, came from within when one of the members of the original Arduino team claimed ownership and took control of the whole project. This led to a lawsuit and an expensive three-year fight.

This conflict was eventually resolved, said Banzi, a story which I had not heard before. The lawsuit was settled with an agreement that the two entities would share ownership of Arduino but Banzi had an option to buy out the other side if he raised the money in six months. He said the other side didn’t expect him to be able to buy them out.

With help from ARM and other investors, Banzi was able to raise the money much more quickly than even he thought possible. He was grateful that these investors valued Arduino and the ecosystem and community that has grown up around it. Banzi said it was an “extremely stressful period of time that he wishes never to go through again.”

Here is a link to Massimo Banzi’s talk.

Open Source Software Successes

Blender and FreeCAD were the subject presentations at FAB25 that demonstrated their success as open source software projects.

Chris Hennes represented FreeCAD, which started as an open source software project in 2001 but just last November released its 1.0 version. The FreeCAD Project Association, located in Belgium, was formed in 2021 as a non-profit with its goal to “support and protect” FreeCAD. In the Q&A session, Chris assured that FreeCAD would always remain free. He also said that they had learned a lot from Blender.

From left, Chris Hennes, Pieter Hijma, Leo McElroy, and Francesco Siddi with the moderator.

Pieter Hijma talked about his particular contribution to the FreeCAD project; he received a grant from the FreeCAD Project Association to work on the problem of variant parts. Variant parts are multiple copies of an original object but might vary with an attribute such as length for each copy. If you change a feature in the original, you’d like to have it propagate to all the copies instead of having to make the same change repeatedly to each copy. That problem was what Pieter solved.

Next was Francesco Siddi from Blender, which is celebrating 30 years as an open source project. Blender is software for 3D modeling, animation, and visual effects. It is used by independent creators as well as commercial studios. Siddi showed a clip from the film Flow that was an Academy Award nominee this year for Best Animated Film, saying that the animations show what Blender is capable of. “This is how a modern 3D workflow looks like when using Blender,” he said. He added that in large companies, Blender is used as a sandbox to try out new ideas. He cited its Python-based API, adding that Blender is “very easy to hack.”

The founder of Blender is Ton Roosendaal, a Dutch art director and self-taught software developer. Siddi talked about the Blender Foundation, the organization behind Blender, which is located in Amsterdam. Its fund development platform is currently raising almost $200K a month. These funds support the Blender HQ in Amsterdam and fifty full-time people working on the project who help to coordinate the work of 1000s of volunteers. Open source projects like Blender are complex organizations with employees, seeking funds and spreading it to independent developers to add or improve features.

Free software once was an option for independent developers, back when software might move from hand to hand via disk at a swap meet. Later, code was shared on online bulletin boards. The Internet not only resulted in new forms of software distribution but led to distributed development projects with lots of contributors and hosted on sites like GitHub. These projects may have a founder like Linus Torvalds or Larry Wall, benevolent dictators who often left the management of updates and features to others. Yet with the Blender Foundation and the FreeCAD Project Association and others like the Apache Foundation, we are seeing them become institutions that have members but also manage organizations that have a professional and clerical staff. To support and protect is their mission, like a trade association or an environmental organization. It is not enough to just have code or designs and make them available online; open source needs the people who make it and the people who use it to organize on its behalf.

What’s Next

Průša did not give specific details about how the company might change its license. “We are working on a new community license so we are feeling more comfortable sharing as much as we used to share again with minimal risk of exploitation,” he wrote in his blog post. “It is so bizarre to me, that we got to a stage where you need to think about protecting your designs and inventions in order to share them with the community …”

One might say that Průša believes that 3D is a strategic industry for the future, much like the Chinese government. “There is no engineering company in the world that does not use 3D printing,” said Průša. A shipping line has 3D printers on board each ship, and they connect to a centralized parts library via satellite to download designs for making parts on demand. He hopes that those firms will be using machines made in Europe or the US. He believes that 3D printing will help reshape the world where things are created close to where they are consumed.

The problem is that the US government and the EU don’t offer the same kinds of support that the Chinese government offers to its companies nor do they look to protect their own emerging industries. “It is a harsh reality that we have lost manufacturing capacity in Europe and US,” he wrote. That’s been our recent history, but we could make changes to protect and support open innovation.

The people who believe in open innovation need something like an institution that can receive funds and protect its interests and its community. Something like what the Blender Foundation that has done for content creators.

All aboard the Maker Train

FAB25 was hosted in two Czech cities, Brno and Prague — I heard that this was a compromise between FabLab Brno and the Prusa team in Prague. To bring attendees from one city to the other, the conference organizers arranged a Maker Train, a dedicated train that made the three-hour trip. It was a great time.

The Maker Train in the Brno station

FAB25 was organized by Jan Dvořáček and the Make More team, whom I’m happy to say also organize Maker Faires throughout the Czech Republic including the largest one in Prague. Josef is proud to say that Czechia has the largest number of Maker Faires of any country in the world!

Make Things is a weekly newsletter for the Maker community from Make:. This newsletter lives on the web at makethings.make.co

I’d love to hear from you if you have ideas, projects or news items about the maker community. Email me - [email protected].